Coffee Processing Explained

What is Coffee Processing?

Ahh, the unsung hero in the coffee chain - coffee processing. The growing and roasting parts always get the glory, now is the time to talk about why processing is so so important to us.

Here at Creature Coffee, we specialize in roasting specialty grade coffee from the world’s best coffee growing regions so we’re always on the lookout for interesting new coffees with fun flavor profiles. We love it when our partner farmers and producers have used interesting coffee processing techniques to create a flavor profile we like. We always have a honey processed something-or-the-other and a fruity naturally processed coffee in our rotation.

But let’s go back to basics first, before I confuse you with all my coffee processing jargon talk. Let’s find out about the reasons for coffee processing, the techniques used and why it has become so important in the specialty coffee industry today.

What does coffee processing actually mean?

This is the process from taking the coffee fruit (cherry) and turning it into two green coffee beans ready for roasting. It’s like taking a stone fruit, and stripping it of skin and fruit, leaving behind a hard stone.

Let me explain in more detail.

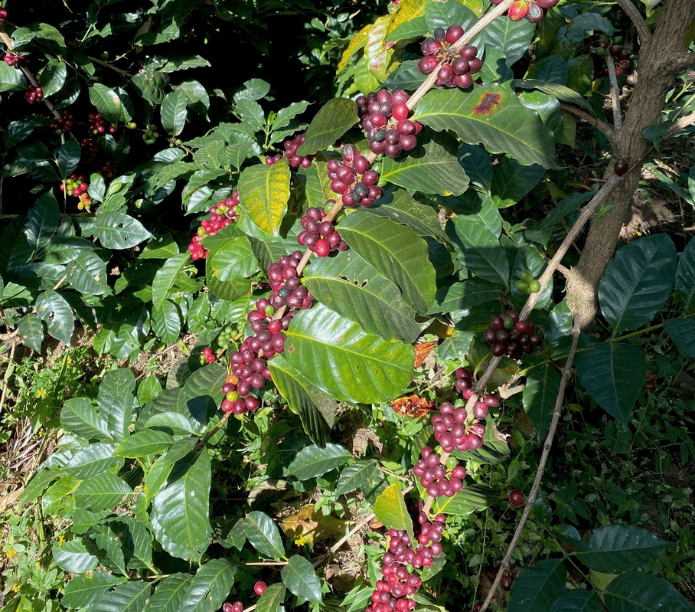

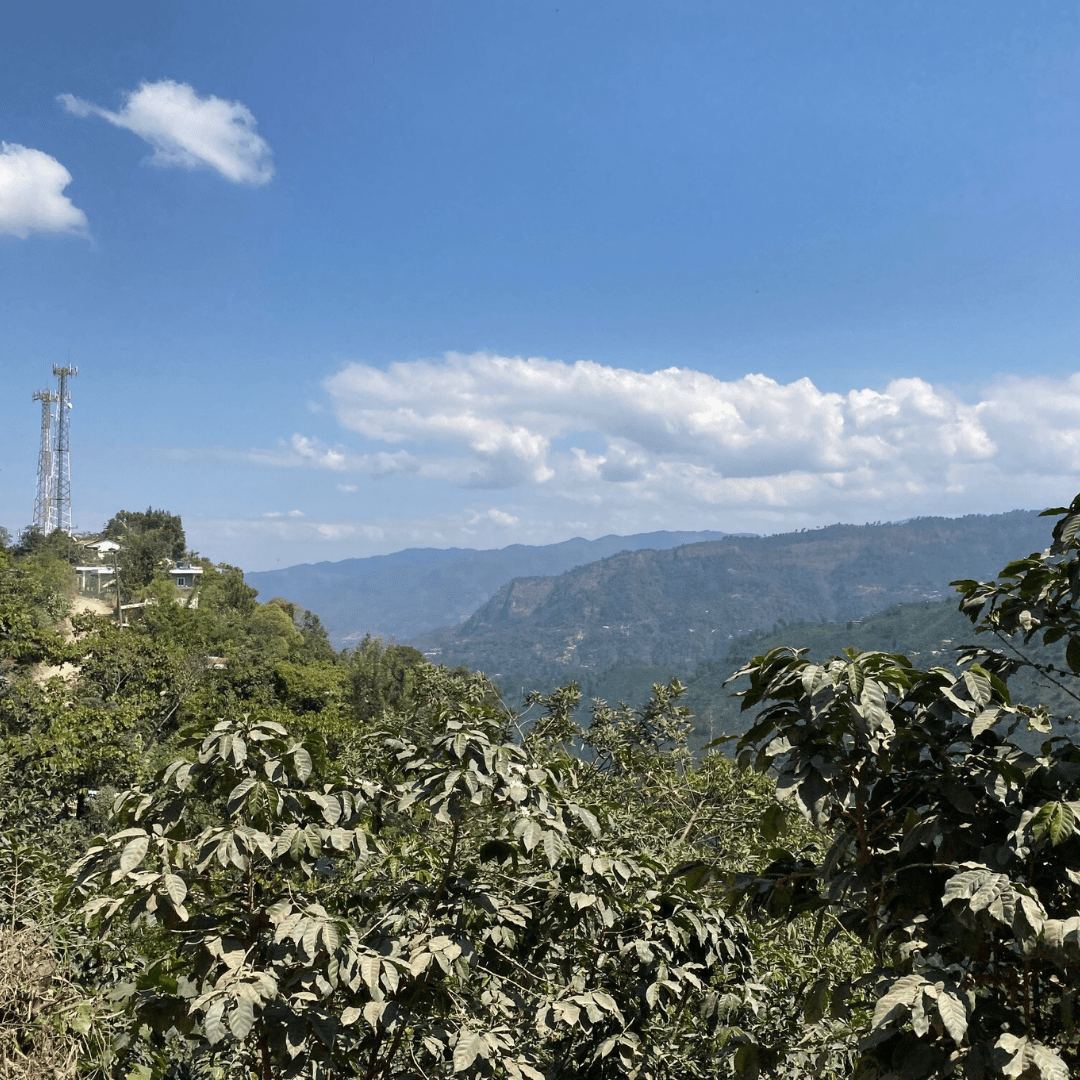

Coffee processing occurs in the country where the coffee plants are grown. The coffee cherries are handpicked on the farm from big green coffee plants, which are grown high in the mountains. The coffee cherries become bright red when they are ripe for picking.

They are then transported in big baskets to be processed at the bottom of the mountain, sometimes many miles away from the farm. This processing part strips the ripe red coffee fruit (skin and pulp) leaving behind two green coffee beans (sometimes one). These beans are then dried and transported to coffee roasters all over the world.

This blog post explores the many different ways to process coffees, and how this coffee processing affects the final flavor profile in our morning cup of joy.

Let’s start with the three easiest and clear cut coffee processing methods most commonly used today.

Washed Coffees (or wet processed)

Nowadays, most coffee is washed as it’s the most reliable way to process coffees and produces a clean and crisp tasting cup of coffee. Here’s how it works.

Step 1 - Depulped

The red ripe cherries are put into a depulping machine. This strips the red skin from the fruit (pulp) which still clings to the two rock hard green coffee beans (seeds) inside.

Step 2 - Washed

They are then soaked in water and agitated occasionally to encourage the pulp to fall off the coffee seeds. Depending on the region, resources and processors preferences, the seeds sit in this water fermenting for a few hours up to a couple of days.

Step 3 - Dried

The beans are rinsed thoroughly and then dried on raised beds, or in a mechanical dryer. Climate and resources will dictate how long this takes.

Roasters are always looking for a nice balanced acidity or brightness in the final cup of coffee, and washed coffees produce this. It’s quick and reliable, and it’s extremely rare for this processing method to produce poor tasting coffees. It’s a win win for all parties.

Natural Coffees (or dry processed)

Most people relate to tasting naturally processed coffees as deliciously fruity or wild. Some people absolutely hate the flavors and ruin everything they enjoy about coffee! It all comes down to your personal taste preference really. Here’s how it works…

Step 1 - Dried

The red ripe coffee cherries are placed intact on raised beds, patios, or mats. They are regularly turned so they dry evenly. The coffee beans (seeds) are inside the coffee cherry, soaking in the fruity flavors.

Step 2 - Hulled

Once completely dried they are either hulled straight away or can also be stored for months before being hulled. Hulling removes the dry skin and pulp (fruit) of the coffee cherry. All that remains are two green coffee beans (seeds). No washing is needed.

Once upon a time, all coffee was naturally processed in places without reliable access to water, like parts of Ethiopia, Tanzania and Yemen. Natural processing makes sense where temperatures are hot and the sun is powerful as the coffee cherry has little chance to mildew. Humid climates will find it hard to produce naturally processed coffees.

Natural coffees are noticeably different from washed coffees. The longer contact time with the fruit means the coffee beans exhibit a fruit forward or red wine flavor profile with greater body and lower acidity. Even newbie coffee drinkers will be able to pick out blueberry or strawberry tasting notes. We regularly source naturally processed coffees from Ethiopia and Uganda and really enjoy how different they taste from their washed counterparts. Check out some of our playful coffees here.

Honey Processing (or wet-hulled)

Firstly, no honey is used in the making of honey processed coffees, it’s more of a reference towards their sweet flavor profiles. The actual process lies somewhere in the middle of washed and natural processing and the techniques used are up for interpretation depending on the country and region where the coffee is grown. Places like Kenya, Costa Rica, Brazil, and Sumatra all have their own unique processes and rules, so it’s hard for us coffee professionals to even pinpoint just one universal process. But I tried... and here it is!

Step 1 - Depulped

The red ripe coffee cherries are mechanically depulped, removing the skin but leaving a specific amount of fruit (pulp) on the two green coffee beans inside.

Step 2 - Dried

Like natural processing, the beans with pulp attached are taken to raised beds/patios and left to dry. Soaking in the sweet juices of the pulp, they lie in the sun for a day or two.

Honey processing is most common in Central and South American countries due to the climate and access to resources. Honeyed coffees take some of the best flavor attributes of naturally processed and washed coffees combined.

There are also defined techniques such as black, red, yellow and white honey processing. Black Honey leaves the most pulp on the beans and the White Honey leaves the least pulp, changing the color of the bean accordingly. In theory, the black honey will taste more like a fruity natural, the white honey will taste closer to a washed coffee.

Unique Coffee Processing Methods

Pulped Natural Process

Used throughout Brazil, it’s similar to honey processing. It uses a bit more water and strips the beans fully during the depulping process.

Kenya Style

Kenya has its own thing going on! They ferment their coffees for much longer and wash them with the post fermentation water. This highlights a bright and crisp acidity that Kenyan coffees are renowned for.

Anaerobic Fermentation (oxygen-free)

New and very popular in the fancy schmancy coffee world, anaerobic coffees are fetching some very high prices on the market. The anaerobic fermentation process is similar to the washed process but fermentation is completed in fully sealed and oxygen deprived tanks, with no water. Anaerobic processed coffees are relatively rare and very experimental, yielding often wild, unexpected and complex flavors. We’ve tasted coffees that blew our minds with sweet cinnamon candy tasting notes and occasionally, some tasting totally rank, with over fermented nasty tasting notes!

Carbonic Maceration

Think of this as the wine world’s coffee processing technique! The carbonic Maceration method is similar to the anaerobic fermentation method but the cherries are fermented as a whole. The process breaks down the cell walls of the fruit flesh from inside out, soaking in the fruit flesh during the fermentation. Carbonic maceration yields extremely crazy and incredible flavors such as red wine, whisky, banana and bubblegum to the cup.

What happens after the coffee has been processed?

This is the slightly less interesting part of the coffee beans journey. The dry green coffee beans still have a parchment layer and the moisture content is now low enough to be stored without rotting. These beans are usually stored for 1 - 2 months before they are hulled in a dry mill to remove the parchment layer. Then the grading and sorting with machines begins!

Once they are scored and graded, they are put into custom brown jute bags and shipped via shipping containers to roasters around the world. We select ethical importers who take care of this process. They are the vital link between roaster and farmer. Transporting coffee beans is a long journey but green coffee isn’t like roasted coffee, it has a much longer shelf life.

Why is the coffee processing part so important?

The soil, climate, elevation, and coffee varietal will always affect the flavor in the cup, but the processing techniques can enhance, change and improve the final flavor too. Sometimes, good processing can take a good coffee to an excellent coffee. This means more money for the farmer and his workers and the community as a whole. Done right, it’s a win win for the entire coffee chain.

Communication between roaster and farmer has improved in recent years, which has led to an increase in experimental processing techniques. This is great for us coffee geeks, who are always searching for the next best coffee to enlighten our hungry palate. And we’re always happy to pay the farmer/producer more for their craft.

The risky side of coffee processing

Coffee plants harvest every 6 or 12 months. If the processing of good quality beans goes wrong and they taste over fermented and foul, the farmer has lost a lot of money. This indeed is a gamble as low graded coffees will not bring in the high prices expected. If they get it right, they can look to gain more money per bean, but getting it wrong can affect many people’s lives and incomes in a negative way for many months if not years to come.

Sometimes, in order to take the risks, larger global coffee companies are sponsoring research which takes away the risk for the teams in the country of origin.

Final thoughts

Each stage of the growing, processing, roasting and brewing is a science, and it must be done right so our coffee can taste joyous and wonderful in that mug of yours. The processing is a vital part of this coffee chain with many unsung heroes in wet and dry mills across the globe. Keep a look-out on our website for some fun and interesting processed coffees. Hopefully, you’ll be able to pick your favorite processing techniques and taste the differences in them. Team Creature is excited for the world of specialty coffee in the next few years, and we’re stoked to be a part of this continuing global learning experiment into coffee processing and its flavor enhancing potentials.